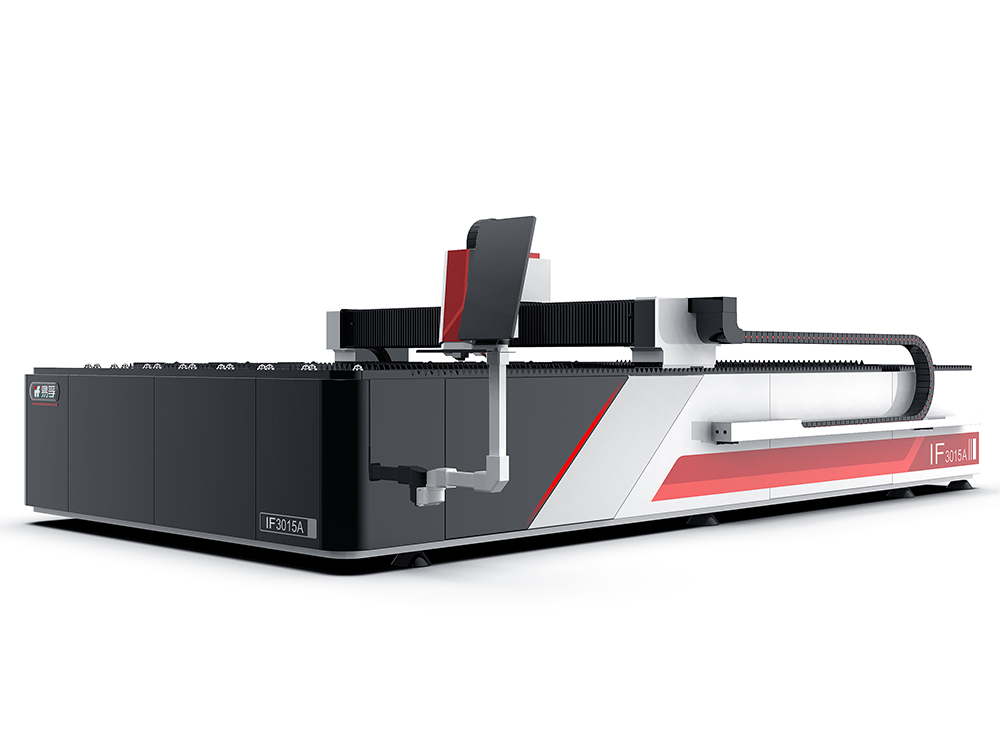

In the world of industrial manufacturing, precision and efficiency are paramount. When it comes to cutting various materials with accuracy and speed, fiber laser cutting machines have emerged as a game-changer. In this article, we will explore the remarkable capabilities and benefits of fiber laser cutting machines, revolutionizing the manufacturing industry.

Unparalleled Precision:

Fiber laser cutting machines from China Fiber Laser Cutting Machine suppliers are renowned for their exceptional precision. Equipped with advanced laser technology, these machines can cut through a wide range of materials with remarkable accuracy, creating clean and precise cuts. Whether it’s metal sheets, plastics, or even delicate materials like fabrics or ceramics, fiber laser cutting machines excel in delivering intricate and precise cuts, ensuring high-quality end products.

Versatile Material Compatibility:

One of the significant advantages of fiber laser cutting machines is their versatility in handling various materials. From stainless steel and aluminum to brass, copper, and even non-metallic materials like acrylic and wood, fiber laser cutting machines can handle a diverse range of materials with ease. This versatility makes them invaluable in industries such as automotive, aerospace, electronics, and signage, where different materials need to be precisely cut to meet specific requirements.

Speed and Efficiency:

Fiber laser cutting machines offer exceptional cutting speed and efficiency, significantly reducing production time and costs. The laser technology employed in these machines allows for rapid cutting speeds, enabling manufacturers to meet tight deadlines and increase productivity. Moreover, the high energy density of fiber lasers results in faster cutting processes, optimizing material usage and minimizing waste. This efficiency translates into cost savings and improved overall manufacturing efficiency.

Enhanced Automation And Precision:

Fiber laser cutting machines are often equipped with advanced automation features, further enhancing their precision and efficiency. Many models offer computer numerical control (CNC) capabilities, allowing for precise control and automation of the cutting process. This automation eliminates human error and ensures consistent and accurate cuts, even for complex designs and intricate patterns. Additionally, some machines incorporate intelligent features such as automatic material detection and adjustment, further streamlining the manufacturing process.

Minimal Maintenance And Operating Costs:

Compared to traditional cutting methods, fiber laser cutting machines require minimal maintenance, resulting in reduced downtime and operating costs. The solid-state fiber laser technology used in these machines has a longer lifespan, requiring fewer maintenance interventions and consumables. Additionally, fiber lasers are more energy-efficient than other types of lasers, contributing to cost savings in the long run. These factors make fiber laser cutting machines a cost-effective solution for manufacturers, improving profitability without compromising on quality.

Send Us A Message