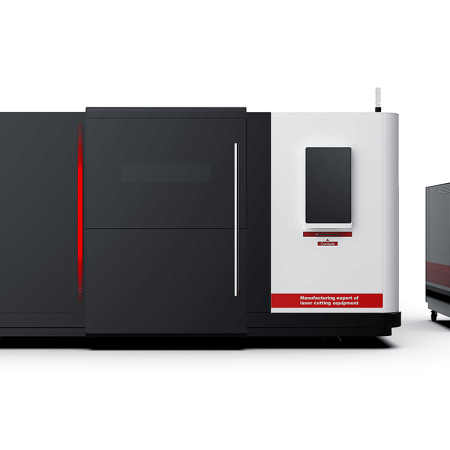

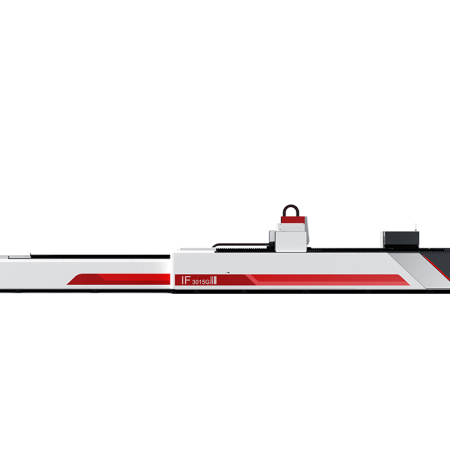

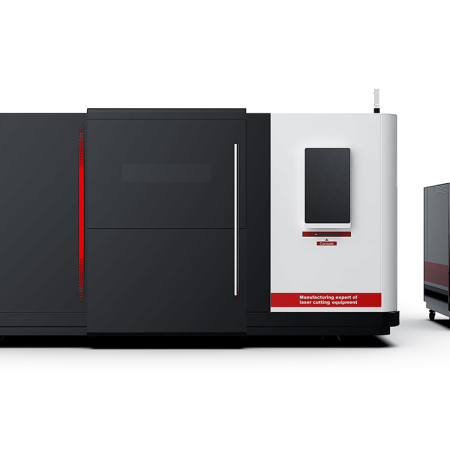

Metal Sheet Laser Cutting Machine

From China metal sheet fiber laser cutting machine factory

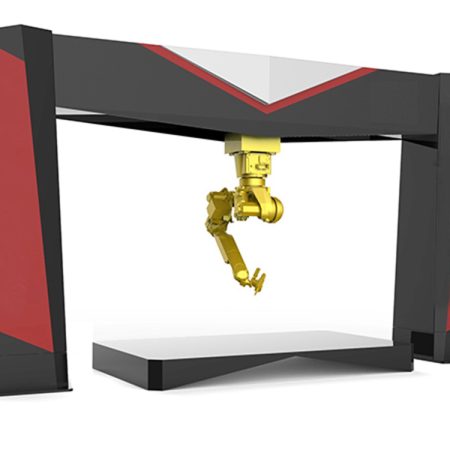

IFtech is trusted fiber laser equipment manufacturer in China. Since the beginning of the history of IFtech, we have been developing better laser technology applications to achieve better cutting. And attach great importance to innovation. IFtech insists on focusing on a single category of laser cutting machines, achieving full coverage of products in the 1000W-40000W power range. By subdividing product categories, IFtech accurately empowers customers, provides customized and professional metal cutting solutions, and effectively creates value for oversea customers. Meanwhile, hot sale metal sheet laser cutting machine is one of the products in our catlogue list.

Metal sheet Laser cutting knowledge you need to know

Laser cutting is a thermal separation process. The laser beam strikes the surface of the material and heats it strongly, melting or completely evaporating it. Once the laser beam completely penetrates the metal material at a certain point, the actual cutting process begins. The laser system follows the selected geometry and separates the metal sheets in the process. Depending on the application, the use of process gas can have a positive impact on the results. Metal sheet laser cutting machine is the recommandation from us, but whether you consider to know what difference between fiber lasers and CO2 lasers?

Fiber lasers V.S. CO2 lasers

Fiber lasers cut metal more faster, At the same time with smaller beams, so they are more accurate and consume less power. In the long run, metal sheet laser cutting machines are also easier to use and cheaper to maintain.

CO2 lasers are produced by sending electricity to glass tubes filled with carbon dioxide and other gases. It may be cheaper, but they always require oxygen or nitrogen as an auxiliary gas and are limited to cutting metals with low reflectivity.

.png)

-450x450.png)