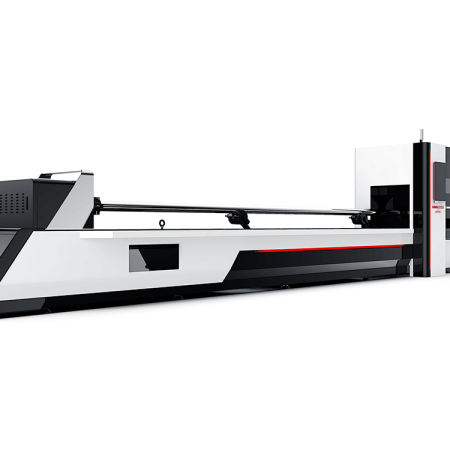

Metal Tube Laser Cutting Machine

Fiber laser is a new technology in laser cutting field. At the industrial level, they are often used to cut thin metal sheets and metal tubes for production parts. Now, they are still expensive machines, but they do have many benefits, including power efficiency and fewer moving parts. Through the trusted laser cutting euqipment manufacturer, it will be good choice for purchasing quality metal tube laser cutting machine.

Metal tube through laser cutting

The laser cutting machine for cutting metal plates can replace a plate in a few seconds. The same operation can also be completed on the metal tube laser cutting machine. But it’s a completely different story about how it was done.

The metal tube laser cutting machine has no standard material tower. Tube bundle loader is the most efficient tube processing option, which sends one tube in the tube bundle to the tube laser at a time through the separation system. This type of feeding mechanism is not suitable for open profiles. Such as angles or channels, because they are interlocked when binding and are not easy to release. For open profiles, step loaders are used, which sequence one section into the machine at a time while maintaining the correct orientation of the section.

Application to wide-range metal materials

A laser metal tube cutting machine is an automatic CNC pipe cutter that uses a fiber laser beam to cut a variety of metals. It includs stainless steel, carbon steel, mild steel, tool steel, alloy, aluminum, brass, copper, bronze, and titanium, into round tubes, square tubes, rectangular tubes, oval pipes, elliptical pipes, hexagonal tubes, triangular tubes, and some custom special shape pipes, etc.

It is a dieless cutting technology that allows metal pipes to have any kind of design cut into them at any angle or orientation. The fiber laser tube cutter is simple to operate with a high degree of automation, low cost, high speed, and excellent quality. And the laser-cut metal accuracy is significantly greater without grinding. Additionally, it is in comparison to flame cutting, plasma cutting, wire cutting, and water jet cutting.

Features of Laser metal tube cutting

The resulting cut is only slightly larger than the laser beam itself. This makes it possible to cut very fine geometric shapes of any shape.

The laser cutting machine will not wear. For example, the tool head will not become blunt. This saves the cost of continuing operations.