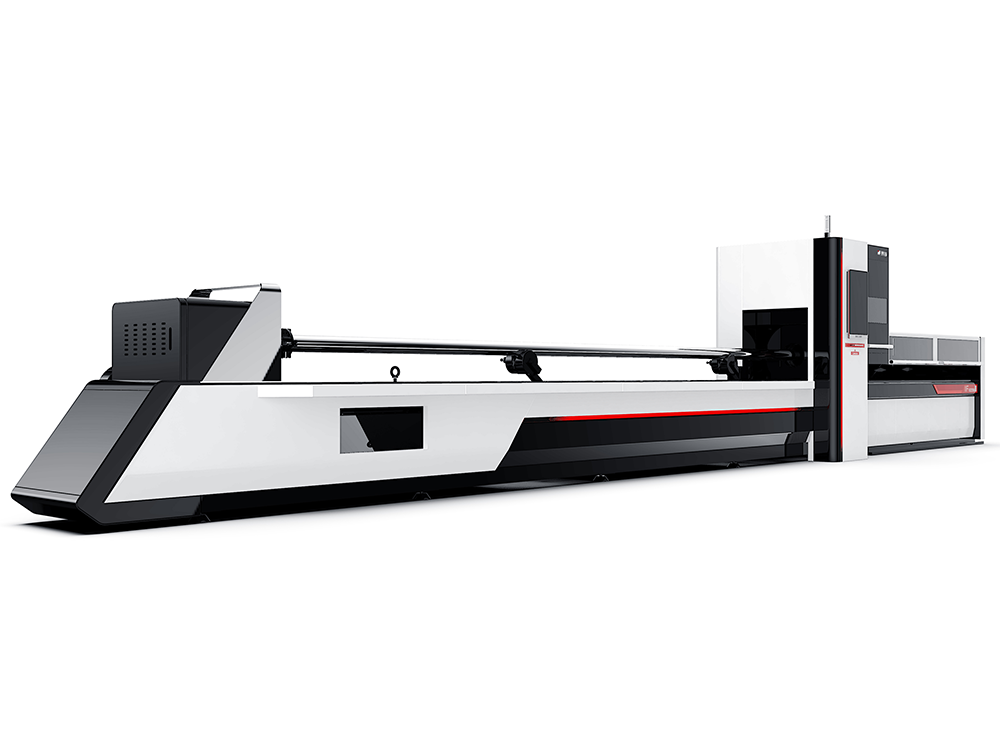

IF60220M Series full-automatic metal tube laser cutter is also called tube laser cutting machine,which can complete a variety of cutting shapes tubes, the tube surface arbitrarily complex curve graphics processing, graphics difficulty without restrictions. After cutting the tube section does not require secondary processing, it can be welded directly, greatly reducing the production period, creating enormous value for the enterprise. It adopts very thin laser beam which can be used on small part cutting and complicated patterns and reach to a polished effect. IF60220M Series full-automatic metal tube cutting machine is equipped with fiber laser device, laser power from 1kw to 6kw.It can cut lines and holes with different diameters from different directions on the tubes&pipes and cut column and crossed lines at the end of branch pipe to meet centrifugal and non-centrifugal vertical intersection condition for branch and main pipe axis.It can cut inclined with the main circular pipe.It can cut branch pipe intersected with the main circular pipe.It can realize angle groove face, square hole, waist-shaped holes cutting.Two rotary tables use double driver synchronous drive, metal tubes are not easily destroyed when processing, with high precision and high processing efficiency.

Application

IF60220M full-automatic metal tube laser cutting machine can cut the following metal tubes: round tube, square tube, rectangular tube, D-shaped tube, triangle tube, elliptical pipe and other diameter imaginable special-shaped pipe angle steel, channel steel and H-shaped steel.

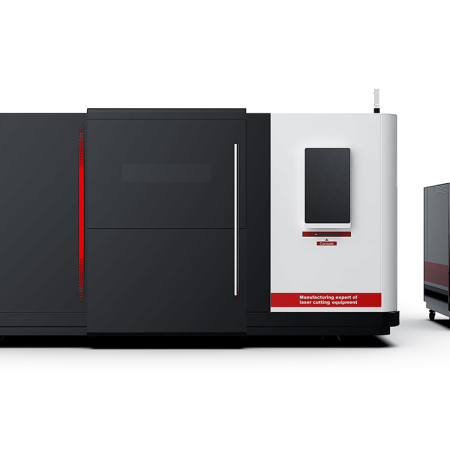

Features

1. Automatic Loading and Unloading,Labor Saving and Easy Operation.Through the numerical control system to realize the loading and unloading, automatic collection of finished products and materials, saving labor costs and improving cutting efficiency.The material rack bears 3 tons, batch processing is pressure-free, and the workpiece is anti-scratch design

2. Professional Full Double Pneumatic Chuck, intelligent pneumatic opening clamp,greater clamping force, no loosening or slipping of heavy pipes, adapting to tubes of different shapes.It is unnecessary to change claws while clamping 10-220mm tubes.Ultra-short tailings, saving the cost of raw materials.Conveying material is more stable, reducing non-production time and increasing productivity.

3. The core drive components and control system are imported parts, with high acceleration and stable dynamic performance.It can realize automatic feeding, alignment and measurement of tube material, and realize efficient cutting.

4. It is welded by thick steel plate, the current mainstream bed structure, high stability.Adopt overall welded and annealing heat treatment technology to eliminate.the machine stress, good rigidity and high accuracy, to ensure the prolonged use without deformation.

5. The electric control box is equipped with intelligent temperature control system to realize stable operation under various extreme weather conditions such as high temperature and low temperature.The intelligent dual temperature control cold water system realizes the independent control of the laser and the optical system, and realizes the stable operation in the harsh environment.

6. It can process and cut a variety of different tube shapes, sizes and thicknesses. It supports high-precision and high-efficiency cutting of square tubes, round tubes, racetrack-shaped and elliptical tubes, as well as angle steel and channel steel.

7. Advanced CNC control system, it can read AI,PLT,DXF,Dst,Dwg and LAS directly, easy to operate.

Industry application

Cut exhibition

-450x450.png)

Send Us A Message